|

Featuring

Refregeration Plants |

| Power

saver finned bunker system |

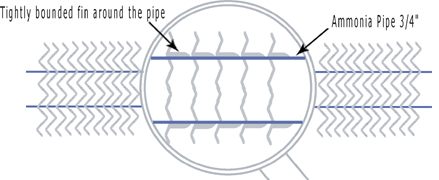

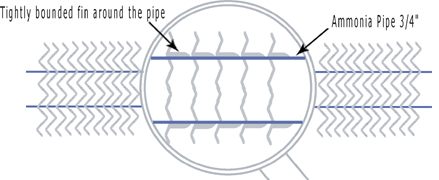

We

have successfully developed finned pipe for bunker system

for cold storage. This System saves Space, Gas & Electricity

Because we are using 3/4" pipe instead of 1-1/4"

which saves the cost. Galvanised fins are bounded tightly

around the pipe. This system is highly efficient which saves

time and money. Putting up our new system you will reduce

your expences on maintenance.

Click to enlarge

|

|

|

We

can also take turn key job as per requirement including Designing,

Erection & putting the system into operation.

For further information write to us or send details of your

cold storage & our engineers shall be glad to receive

your enquries. Beyound commissioning we assure for trouble-free

performance year after year.

|

|

|

Comparison chart for electric consumption of cold storage

Example: Storage capacity of 50,000 potato bags x 50 Kg.

| Diffuser System |

| Horse Power |

6 HP x 4 = 24 HP |

| Running Time |

14 Hrs. Per Day |

| Electric Units Consume |

259 in 14 Hrs. |

| Ammonia Compressor |

KC-3 With 75 HP |

| Electric Units Comsume of Ammonia Compressor |

812 in 14 Hrs. |

| Total electric units consumed in 1 month |

32130 units |

| Cooling Units |

| Horse Power |

3 HP x 5 = 15 HP |

| Running Time |

12 Hrs. Per Day |

| Electric Units Consume |

138 in 12 Hrs. |

| Ammonia Compressor |

KC-3 With 60 HP |

| Electric Units Comsume of Ammonia Compressor |

558 in 12 Hrs. |

| Total electric units consumed in 1 month |

20880 units |

| Finned Bunker |

| Horse Power |

50 Fans x 75 W = 5 HP |

| Running Time |

10 Hrs. Per Day |

| Electric Units Consume |

39 in 10 Hrs. |

| Ammonia Compressor |

KC-3 With 60 HP |

| Electric Units Comsume of Ammonia Compressor |

465 in 10 Hrs. |

| Total electric units consumed in 1 month |

15120 units |

Note: This details are with reference according to world storage standard, but the temperature varies from place to place.

|